Gate valves and line blind valves are both used to isolate sections of piping systems, but they operate on fundamentally different principles. Gate valves are commonly found in oil and gas, water treatment, and chemical processing, valued for their ability to open or close the liquid or gas flow. Line blind valves, like the ZZJG Quick Action Line Blind (QLB), Providing human-level security protection. The differences in the design, operation and application of gate valves and blind valves will be explored here.

How a Gate Valve Works

A gate valve uses a movable disc (called a “gate”) to open or close the flow of fluid. When fully open, it offers a nearly unobstructed path with minimal pressure drop. However, gate valves are not suitable for controlling flow. Partially opening a gate valve will cause uneven flow, turbulence, and accelerated wear of the valve disc and sealing surface. Gate valves are primarily designed for full open or full closed positions. Typically, they operate at temperatures between 20°C and 60°C and pressures up to around 16 bar. Proper maintenance of packing and internal components is crucial for maintaining sealing, but sealing reliability can decrease over time.

What Is a Line Blind valve?

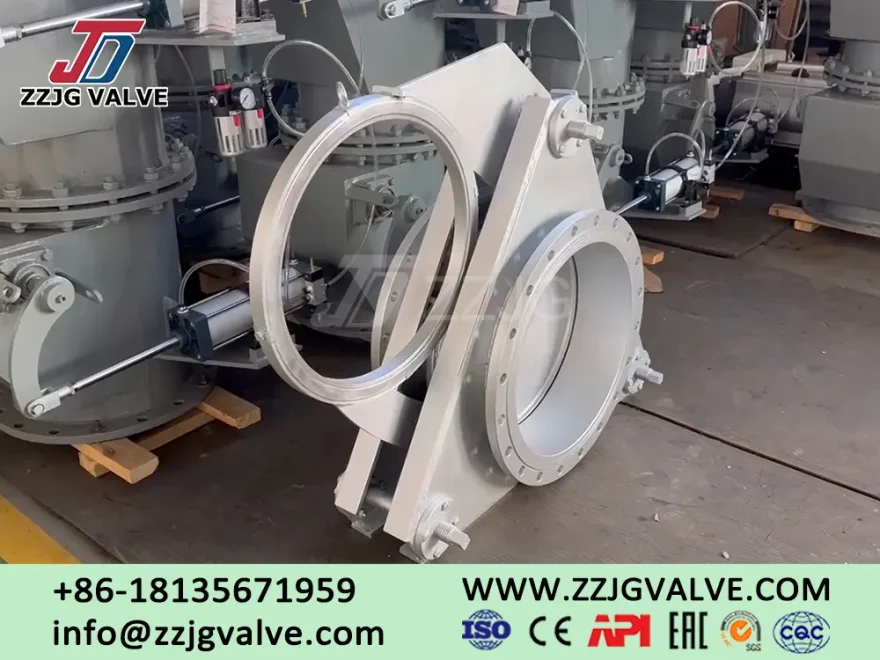

A line blind valve, such as the ZZJG QLB, provides a significantly stronger and more reliable isolation than a gate valve. It’s designed to guarantee a complete physical block between the upstream and downstream sections of the pipeline. The line blind valve works by separating the pipeline flanges and inserting a solid blinding plate (or spectacle plate) that completely blocks fluid flow. ZZJG QLB( line blind valves) can handle extreme temperatures (ranging from -196°C to 650°C) and high pressures (up to 420 bar or higher). Unlike traditional spectacle blinds, the ZZJG QLB can be operated in seconds without tools, drastically reducing downtime and improving operational safety. Line blind valves are classified as “positive isolation devices” providing the highest level of safety for maintenance, equipment protection, and process isolation.

Gate Valve vs Line Blind valve: Four Key Design Differences

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!