In industrial applications, isolating pipes with blind plates or blind valves is a common practice when maintaining, repairing, or modifying piping systems. Understanding and applying blind valves to isolate critical processes such as phenol is important to help protect maintenance personnel and those performing isolation operations who may also be exposed to critical process fluids such as phenol.

The selection of corerct methods, equipment and materials is important to ensure the safety of maintenance personnel and isolation operators.

Here we analyze the hazards associated with phenol piping and highlight the importance of evaluating appropriate methods to protect all personnel involved in the process.

Phenol, also known as carbolic acid, is an aromatic organic compound that is widely used in the production of plastics, pharmaceuticals and other consumer product building blocks. However, phenol itself is harmful to humans and the environment if not handled properly, especially when isolating phenol in pipeline equipment.In short, once phenol leaks, it can easily endanger the lives of people on site.

In the quest to isolate phenol pipelines, it is important to recognize its inherent hazards:

Corrosiveness: Phenol is highly corrosive to humans and some metals. When used for pipeline isolation, it can cause severe corrosion to pipeline materials, leading to potential leaks, bursts and structural damage.

Toxicity: Phenol is highly toxic and can be absorbed through the skin, inhaled, or ingested. Exposure to phenol can cause serious health problems, such as death.

Flammability: Phenol is flammable and, if released into the environment, can form explosive mixtures with air, posing a hazard to nearby workers and associated areas.

The correct way to isolate a critical process

According to the Occupational Safety and Health Administration (OSHA) guidelines, the correct way to isolate a critical process is as follows:

Use a blind valve or blind plate: Completely cover the hole with a solid plate.

Double Block and Vent: Close and lock/tag both shutoff valves and open the drain or vent valve in the middle.

Lockout or Tagout: Ensure all valves are closed and locked or tagged out.

Misalignment: Misalignment or removal of part of a line or pipe.

Disconnection: Block or disconnect mechanical connections.

Other important considerations when isolating equipment are the ease with which operators can perform blind operations and methods to prevent exposure. Mainly include:

Isolation time: The longer the time, the higher the risk of exposure.

Number of people required for isolation: The more people required for isolation, the more people who may be exposed to the process fluid.

Distance from phenol: The closer the operator is to phenol, the higher the risk of exposure.

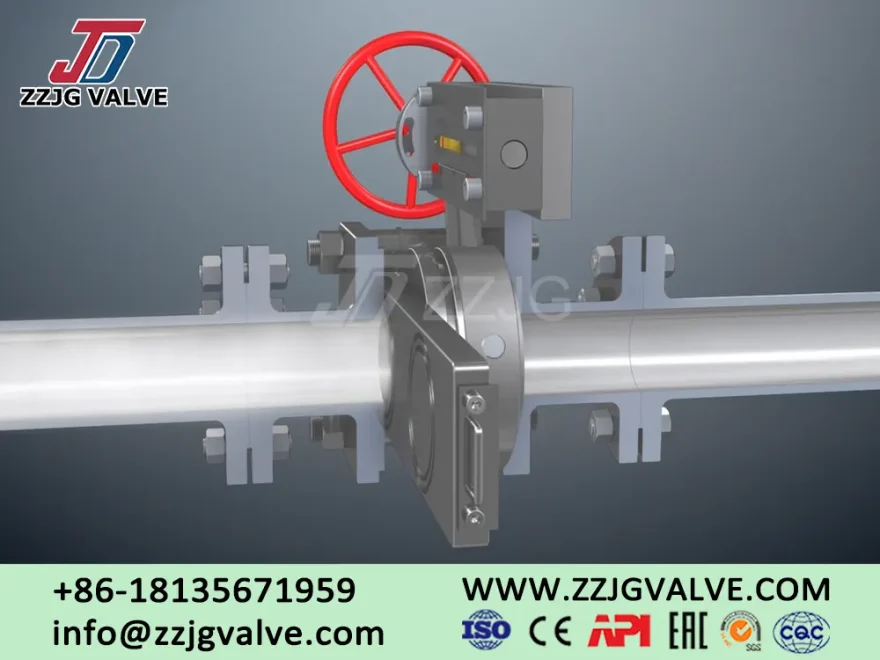

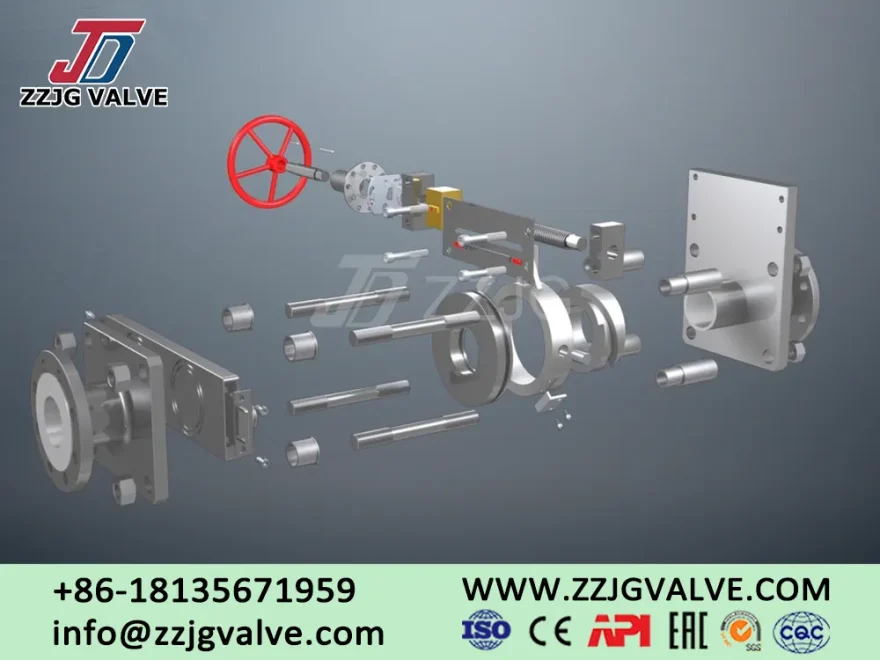

It can be seen that it is particularly important to quickly and safely isolate the phenol pipeline. The quick-cut blind plate valve meets this need very well. Only one person is needed to complete the pipeline isolation on site. More importantly, the time spent is only 1/4 to 1/8 of that of replacing a traditional blind plate, which greatly reduces the possibility of maintenance personnel being injured.

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!