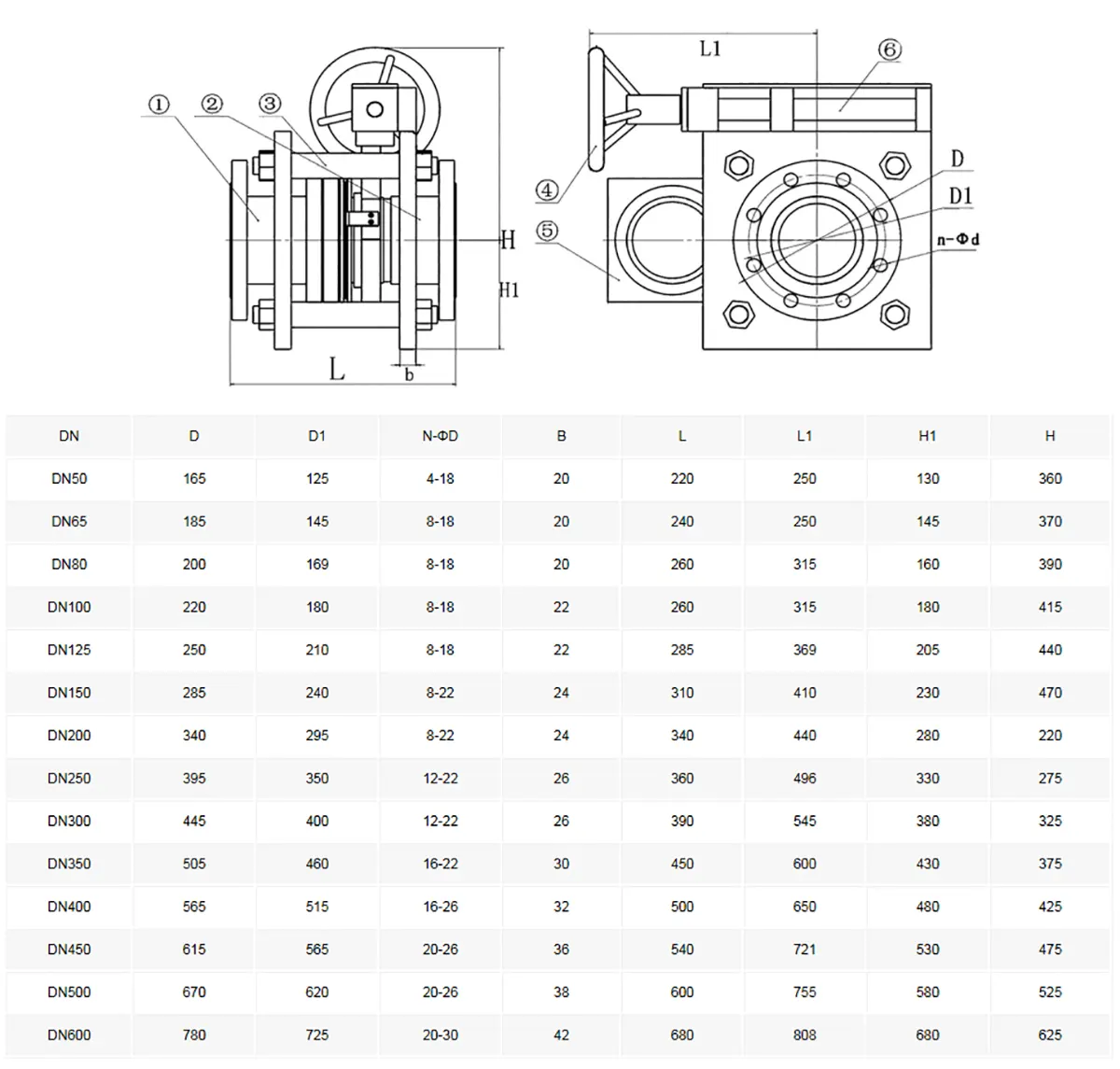

Suitable for small and medium-diameter high-pressure pipelines (typically DN50-DN300), ideal for petrochemical, natural gas, and power grid systems requiring high-pressure fluid control.

Significantly saves labor costs with single-operator functionality, reducing manpower by 50% compared to traditional multi-person operations for pipeline maintenance.

Enables quick operation—completes switching processes in 3-5 minutes, 3-10x faster than manual valves or flange connections for emergency response and frequent workflow adjustments.

Offers electric/pneumatic drive modes: Electric is for automated, precision control in powered environments. Pneumatic is explosion-proof for hazardous areas like oil platforms.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

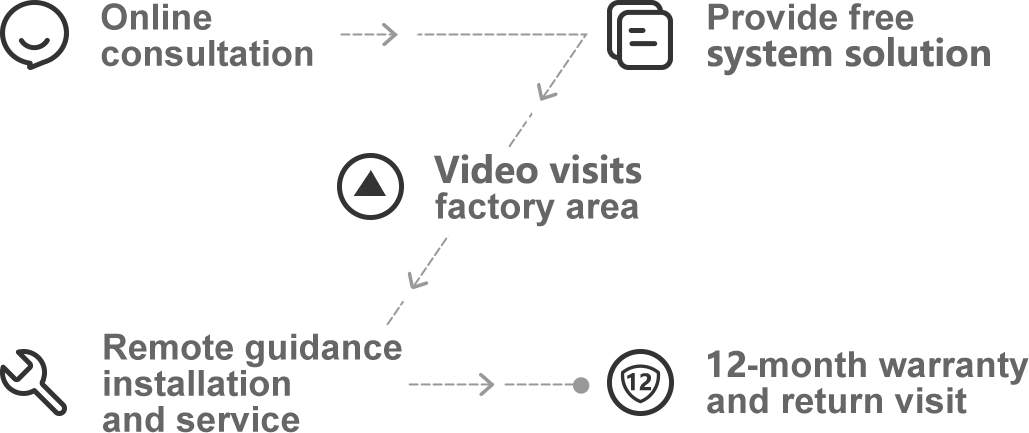

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!