Metal-to-metal sealing via cam-driven blind plate ensures zero leakage, meeting high-pressure safety standards (API 600/6D).

Axial sliding design eliminates need for pipeline expansion, cutting installation time & preventing flange damage.

Evenly distributed high-tensile bolts enhance vibration resistance and bidirectional pressure capability (ASME B16.34).

Cam mechanism enables ≤15-second blind plate movement, with manual force ≤150N and built-in position indicators.

The professional 3D software for structural analysis, material selection and process planning to virtually simulate the reliability of materials under different temperatures, mediums andpressures, and finally validate them through finite element analysis to provide customers with safe and reliable products.

From raw materials to production, sealing performance testing, strength testing, functional testing, to surface quality testing and packaging and shipping, the whole process is strictly in accordance with API standards and support third-party independent organizations to test and certify our products.

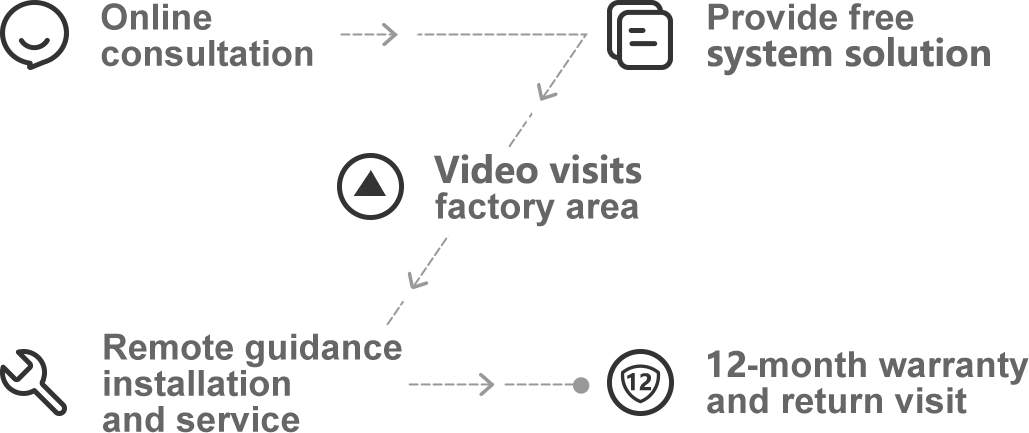

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!