1. Blind plate valves core advantages

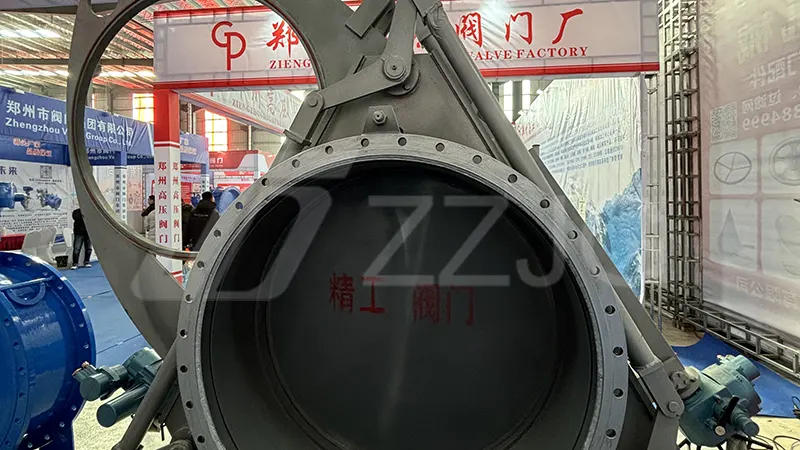

1.1 Double sealing structure: When closed, the valve plate fits tightly with the sealing surfaces on both sides to form a “blind plate” effect. The sealing performance is better than that of ordinary gate valves, and it is suitable for pipelines with strict sealing requirements.

1.2 Compact structure: small size and light weight, easy to install in pipelines with narrow space (such as multi-layer pipeline dense areas).

1.3 Convenient operation: can be driven manually, electrically or pneumatically, suitable for frequent switching scenarios (such as production line switching media or pipeline maintenance).

2. Blind plate valves key requirements for applicable environment

2.1 Pressure and temperature range: low pressure (such as gas pipelines, pressure ≤1.6MPa); medium and high pressure (such as chemical pipelines, pressure ≤10MPa) require high-strength materials. High-temperature resistant blind plate valves can withstand high temperatures above 300℃ (such as gas pipelines in the metallurgical industry).

2.2 Medium characteristics: Gas (such as coal gas, oxygen), liquid (such as sewage, oil), slurry containing solid particles (such as ore slurry, ash) can be applied, but the sealing material (such as rubber, tetrafluoroethylene, metal hard seal) needs to be selected according to the medium.

3. Blind plate valves installation direction

Usually horizontal installation, the valve plate is perpendicular to the pipeline axis; some models support vertical installation, but it is necessary to avoid long-term erosion of the sealing surface by the medium.

Blind plate valves materials and precautions

In summary, blind plate valves are widely used in complex industrial environments with high temperature, high pressure, corrosion, and solid particles due to their high sealing and flexible switching characteristics. They are irreplaceable in workplaces that require “human” safety. When selecting materials, factors such as media, pressure, temperature, and installation dimensions must be considered to ensure that the valve performance meets the use requirements, and at the same time, attention should be paid to daily maintenance to extend the service life.

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!