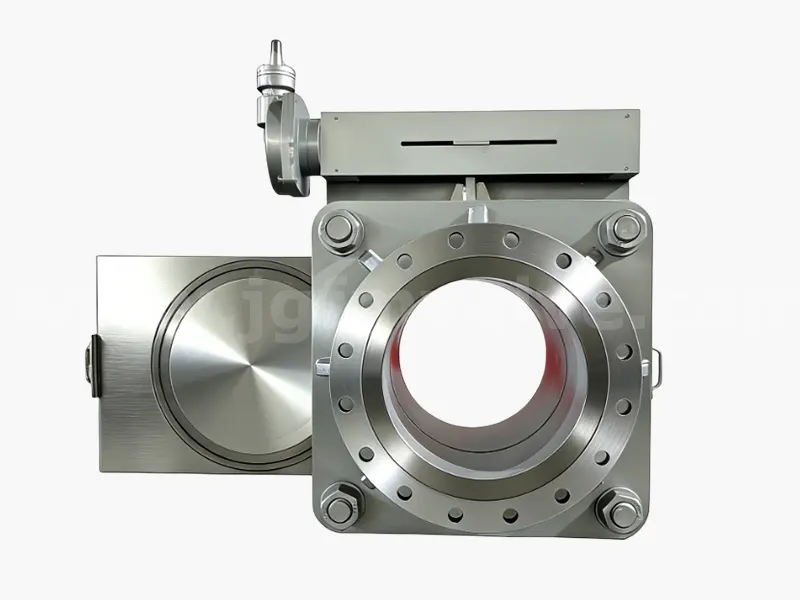

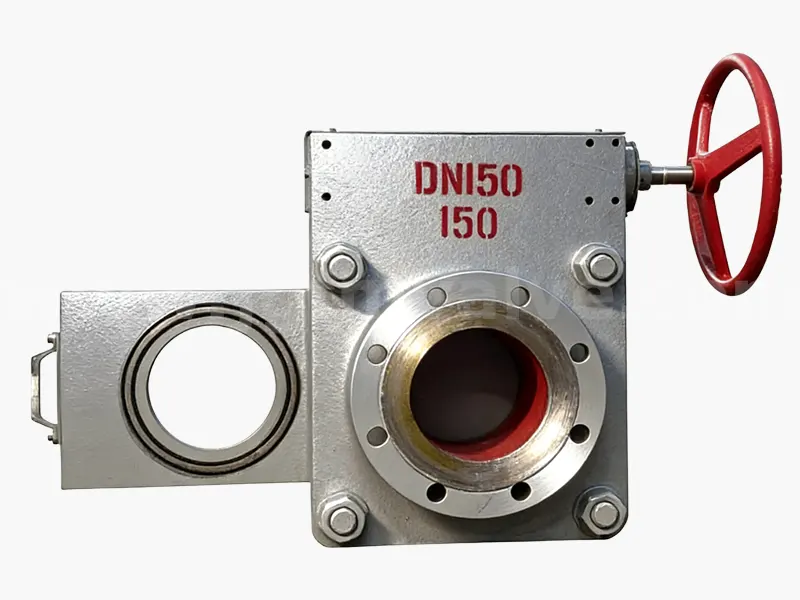

In pipeline systems of metallurgy, chemical industry, petroleum, and municipal engineering, achieving absolute and safe cutoff of media is always a top priority for ensuring the safety of maintenance personnel and maintaining production continuity. Addressing the pain points of traditional valves, such as susceptibility to leakage, jamming, and difficulty in identifying their status in extreme environments, our company has launched blind valves that have undergone in-depth technological iteration, creating a highly reliable “physical-level” cutoff solution. Blind valves (also known as spectacle valves), as critical isolation devices, encompass a full range of models, including electric, hydraulic, and pneumatic types.

ZZJG Blind Valve Features:

I. Absolute Sealing: Safeguarding the Bottom Line of Safe Production The core mission of a blind valve is absolute sealing. Through a unique telescopic mechanism and a rigorous sealing pair design, this product completely overcomes the internal leakage hazards that traditional valves are prone to when cutting off blast furnace gas, flammable, explosive, or highly toxic media. Its physical forced sealing truly achieves 100% shut-off reliability, building a solid barrier for downstream maintenance personnel.

II. Say Goodbye to Jamming: Handling Complex Operating Conditions with Ease Blind plate valves make jamming a thing of the past. In complex operating conditions involving dust accumulation and drastic temperature differences, traditional valves suffer from “scaling and jamming,” becoming a nightmare during maintenance. Our blind plate valves, however, ensure smooth operation and seamless opening and closing in any extreme environment.

III. Visual Indication: Intuitively Presenting Pipeline Status Traditional valve on/off status often relies on instrument panels or small signs, which are prone to visual errors. Blind valves, however, can intuitively and clearly present the real-time status of the pipeline. This “safety at a glance” visual confirmation mechanism effectively eliminates human-caused hazards due to signal delays or blind operations, ensuring that every operation meets the most stringent safety and compliance requirements.

In summary, through structural innovation, line blind valves have completely overcome the core pain points of traditional isolation equipment, such as leakage, jamming, and unclear status. It is not only a “hardcore” piece of equipment for achieving absolute media shut-off, but also a crucial cornerstone for industrial site safety and compliance. As the last line of defense against highly toxic and harmful media, our company’s blind flange valves will continue to define a new level of safety for industrial shut-off with a “zero-error” standard.

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!