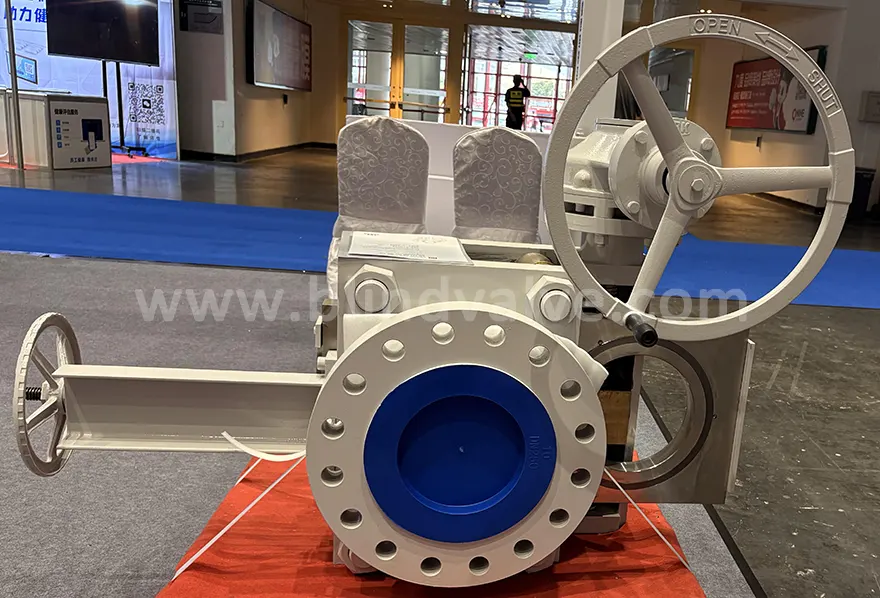

Blind plate valve (also known as glasses valve) is a valve mainly used to cut off pipeline media and ensure pipeline safety. It is composed of valve body, blind plate, valve plate and other components, which can achieve the function of completely isolating the pipeline.

With the popularization of industrial automation and intelligence and the increase in demand for special working conditions, blind plate valves may show special functions in the following aspects in the future:

Ⅰ – Intelligent and automatic control functions

1. Remote electric/pneumatic control:

1.1 Integrated electric or pneumatic actuators, remote automatic opening and closing through PLC (programmable controller) or DCS (distributed control system) or FCS (fieldbus control system), reducing manual operation risks, effectively protecting the lives of maintenance workers, and suitable for high-risk, high-temperature, toxic media and other scenarios (such as chemical, metallurgical, gas pipelines).

1.2 With wireless communication modules (such as 5G, LoRa), it can be connected to the industrial Internet of Things to achieve remote monitoring and centralized management.

2. Real-time status monitoring and early warning:

2.1 Built-in various electrical components, such as pressure sensors, displacement sensors or leakage detection devices, can monitor the switch status, sealing performance and pipeline pressure changes of blind plate valves online, and synchronously feed back data to the central control system to warn of faults in advance (such as aging of seals and loose bolts) to ensure pipeline safety.

2.2 Combined with AI algorithms to analyze operating data, predict maintenance cycles, and reduce downtime and maintenance costs.

Ⅱ – Special working conditions adaptability function

1. High temperature/high pressure/strong corrosion environment

1.1 Adopt new high temperature resistant alloy materials (such as Hastelloy, titanium alloy) or ceramic coatings to improve the corrosion resistance and wear resistance of valve body and sealing surface, which is suitable for extreme working conditions such as nuclear power, coal chemical industry, deep sea oil and gas.

1.2 Optimize the design of triple eccentric or double eccentric structures to enhance the sealing reliability under high pressure and achieve zero leakage (such as API 6D standard requirements).

2. Fast switch and emergency cut-off function

For emergency accidents (such as pipeline leakage, fire), electro-hydraulic linkage, gas-hydraulic linkage or spring energy storage type fast drive device is used to achieve the rapid closure of the blind plate valve within seconds, cut off the flow of the medium, and improve the safety protection level.

Ⅲ – Safety and energy-saving design function

1. Low leakage and zero emission technology

1.1 Double sealing structure (such as metal hard seal + soft seal combination) or bellows seal is used to reduce the leakage rate of volatile organic compounds (VOCs) and comply with environmental protection regulations (such as EPA, IED, China’s “Volatile Organic Compounds Unorganized Emission Control Standard” GB 37822-2019, etc.).

1.2 The sealing surface uses degradable or asbestos-free materials to reduce pollution to the environment.

2. Energy-saving drive and energy recovery

The servo motor or permanent magnet synchronous motor drive is used to reduce the energy consumption of the electric blind plate valve; combined with solar or wind power supply, it is suitable for pipelines in remote areas.

Ⅳ – Multifunctional integration and modular design

1. Blind plate + valve integration

Integrate the blind plate valve with the stop valve, check valve and other functions to reduce the number of pipeline components, installation space and cost, and is suitable for compact industrial devices (such as LNG liquefaction plants and offshore platforms).

2. Modular replacement components

Design removable seal and drive modules to facilitate quick replacement on site and shorten maintenance time; support modular versatility for multiple pipelines (such as DN50-DN2000).

Ⅴ – Safety explosion-proof and fire-proof functions

1. Explosion-proof certification and fire-proof structure

Passed ATEX, IECEx and other explosion-proof certifications, the valve body adopts anti-static design (such as copper alloy sealing surface) to prevent sparks from friction; the fire-proof structure meets API 607 and ISO 10497 standards to maintain sealing integrity in the event of a fire.

2. Mechanical interlock and redundant design

Equipped with a mechanical interlock device to prevent misoperation of the blind plate valve; the drive system adopts a dual-power supply configuration (such as mains + backup battery) to ensure that the valve can still be opened and closed normally during a power outage.

Ⅵ – Digitalization and operation and maintenance auxiliary functions

1. Digital twin and virtual debugging

Through 3D modeling and digital twin technology, the operation status of the blind plate valve is simulated in a virtual environment, the control program is optimized, and design defects are discovered in advance.

2. AR operation and maintenance guidance

Combined with AR technology, real scenes are added to provide visual operation guides for on-site maintenance personnel, such as blind plate replacement steps and troubleshooting processes, to reduce training costs and human errors.

In the future, the special functions of blind plate valves will develop around “intelligence, safety, and efficiency”, which will not only meet the basic cut-off requirements, but also adapt to complex working conditions, environmental protection standards and industrial digital transformation requirements through technological innovation. The specific function realization needs to be gradually implemented in combination with industry needs (such as energy, chemical industry, and municipal administration) and technology iteration.

DO YOU HAVE QUESTIONS? WE ARE HERE TO HELP YOU!